Passive Ventilation – The Key to Repairing

Wet Split Face Block and Brick Buildings

How Our Passive Ventilation and Flashing Designs Work

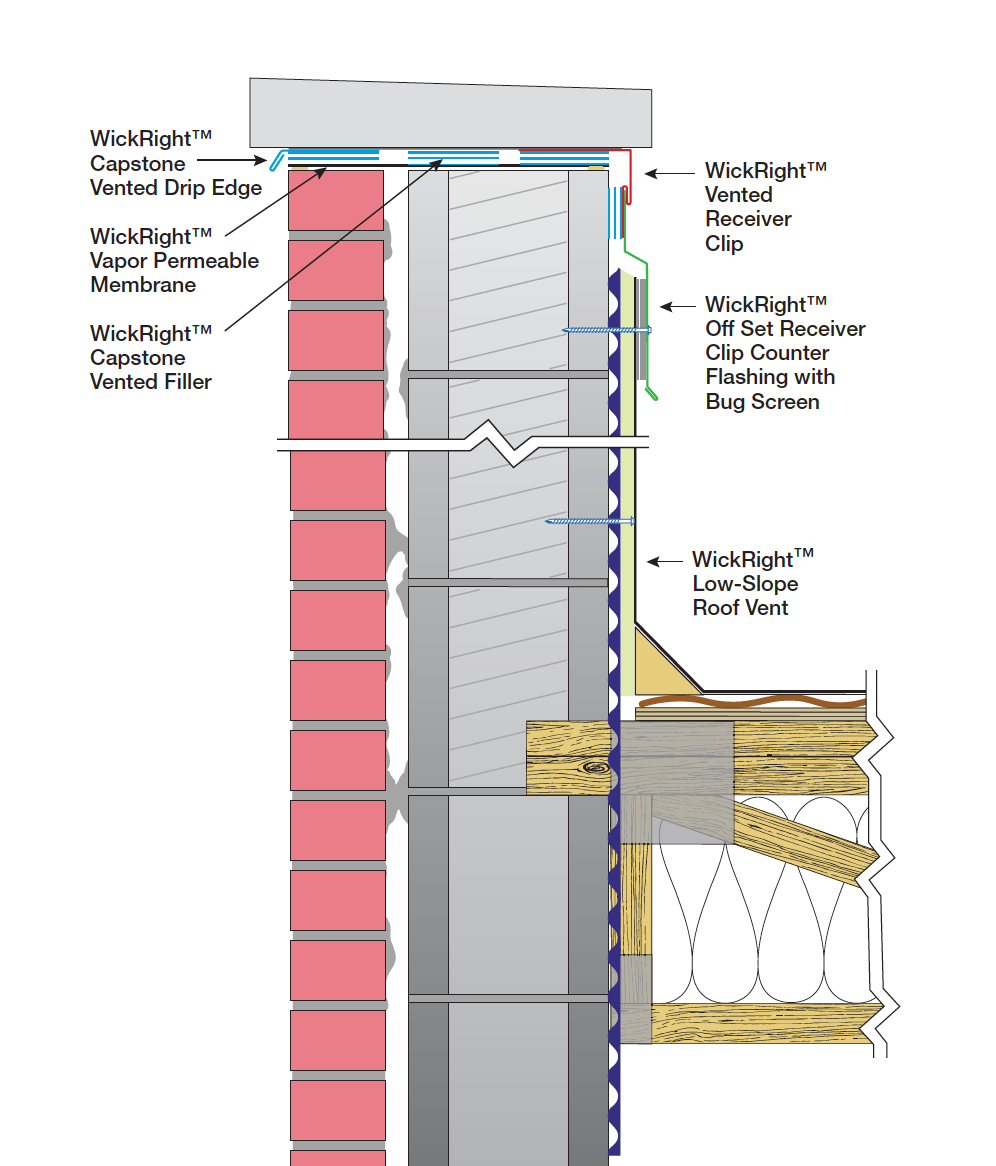

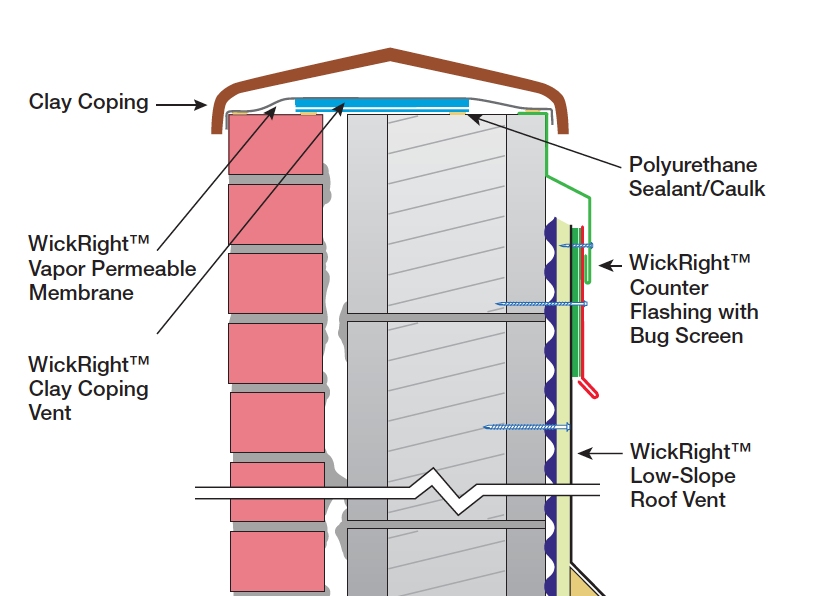

There is a WickRight Passive Ventilation® device for almost every building configuration. But if you have unique situation, Bob Kelly will design a custom device or repair for your building. These illustrations show the most commonly installed WickRight products:

1. Patent-Pending

WickRight Vapor Permeable Membrane™ –

Our membrane is installed on top of the parapet wall with capstones. Allows moisture vapor to exit the wall and protects against moisture intrusion because water molecules are too large to pass through it.

2. Patented

WickRight Capstone Vented Drip Edge™ –

Our vented drip edge is installed on top of the Membrane, typically on the exterior side of the a parapet wall under a capstone. It protects the parapet wall from moisture intrusion and allows fresh air to pass over the top of the wall.

3. Patent-Pending

WickRight Vented Receiver Clip™ –

Our vented receiver clip is installed on top of the Membrane on the interior side of the parapet wall. It acts as a combination Capstone Vented Drip Edge with a built-in receiver clip for our Off Set Counter Flashing that protect the Roof Vent.

4. Patented

WickRight Roof Vent™ –

Our roof vent is installed vertically against the parapet wall at the junction of the parapet wall and the roof deck. It acts as a linear chimney, exhausting heat and moisture vapor from the roof system.

5.

WickRight Counter Flashings and Bug Screen

–

protects the top of the WickRight Roof Vent from moisture intrusion and the bug screen prevents insects from entering the building.

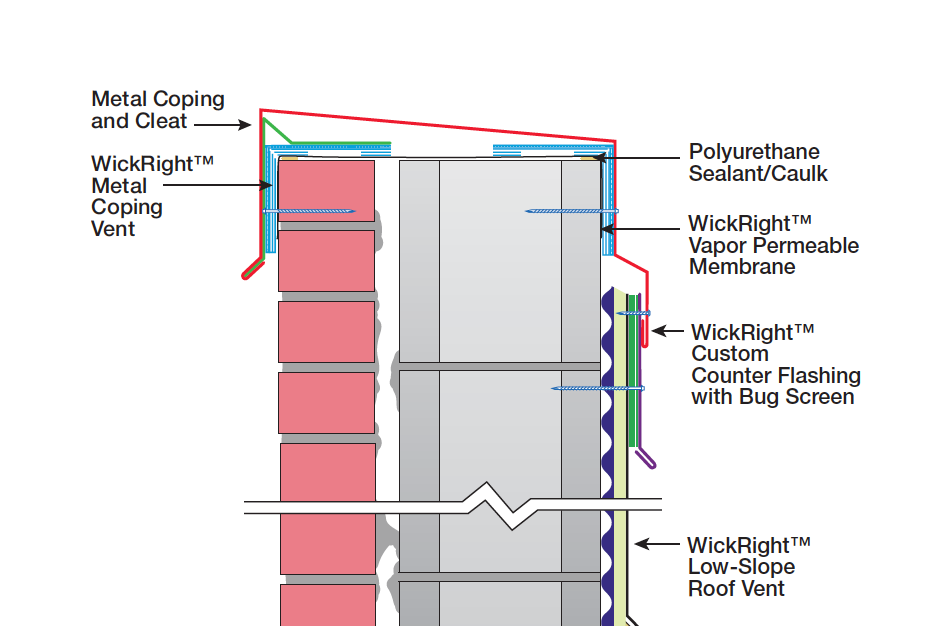

6. Patented

WickRight Metal Coping Vent™ –

Our metal coping vent is installed on top of the parapet wall under metal copings (and on some mansard roofs). It allows air flow over the top of the wall and moisture vapor release from the wall core.

Our metal coping profile is designed to protect the parapet wall from wind driven rain on both sides. The exterior leg of our metal coping profile is a 5" deep. On the interior side of our metal coping profile is a built-in receiver clip to attach counter flashing.

When installed with WickRight Roof VRS, the interior side of our metal coping profile protects the entire interior side of the parapet and acts as a roof termination.

7.

WickRight Clay Coping Vent™ –

Our clay coping vent is installed on top of the parapet wall under our Vapor Permeable Membrane, under clay copings. It allows air flow over the top of the wall and moisture vapor release from the wall core. The Vapor Permeable Membrane protects the wall from any moisture intrusion or condensation build-up.

We have a unique installation technique for clay copings that prevents moisture intrusion between the clay bells. We also have a custom Counter Flashing Receiver Clip profile for use under Clay Copings when the WickRight Roof Vent is installed that protects the interior side of the parapet.

View WickRight Passive Ventilation installations

Click to check out

WickRight Truss Reinforcement Brackets

Computational Fluid Dynamic Simulation –

WickRight Metal Coping Vent

Winter 30º F: Simulation video shows how a 14 mph wind enters the Coping Vent, the wind passes across the top of the wall and into the open block cores, then exits on the opposite side of the wall. This creates

6.4 cubic foot per minute (cfm) of fresh airflow per foot

of wall length, and

2.27 pounds of lift force (lbf) per foot

of wall length to draw moisture out of the wall.

Summer 80º F: Results indicate that when a 18 mph wind enters the Coping Vent, the wind passes across the top of the wall and into the open block cores, then exits on the opposite side of the wall, it creates

7.2 cubic foot per minute (cfm) of fresh airflow per foot of wall length, and

7.87 pounds of lift force (lbf) per foot

of wall length to draw moisture out of the wall.

MENU

GET IN TOUCH

WickRight General Contracting LLC

16365 W. Arlyd Rd., Prairie View, IL 60069

(312) 720-1467

Chicago Licensed Contractor #TGC-065264

IL Licensed Roofer #104017524

Fully Bonded & Insured

STAY CONNECTED

Contact Us

We will get back to you as soon as possible

Please try again later

FOLLOW US ON:

WickRight General Contracting serves

Chicago

and the following neighborhoods:

Albany Park,

Andersonville,

Avondale,

Belmont/Craigin,

Boystown,

Bucktown,

Buena Park,

Edgewater,

Edison Park,

Forest Glen,

Gold Coast,

Goose Island,

Hermosa, Humbolt Park,

Hyde Park,

Jefferson Park,

Kenwood, Lakeview,

Lincoln Park,

Lincoln Square,

Logan Square,

Magnificent Mile,

Margate Park,

Near North Side,

Near West Side,

North Center,

North Park,

Norwood Park,

Old Irving/Irving Park,

Printer’s Row,

Old Town,

Ravenswood,

River North,

River West,

Rogers Park,

Roscoe Village,

Streeterville,

The Loop,

Ukrainian

Village,

Uptown,

West Loop,

West Town,

West Ridge, Wicker Park,

Wrigleyville

WickRight General Contracting also serves the following Chicago suburbs:

Arlington Heights,

Bannockburn,

Buffalo Grove,

Deerfield,

Deer Park,

Des Plaines,

Evanston,

Glencoe,

Glenview,

Highland Park,

Kenilworth,

Lake Bluff,

Lake Forest,

Libertyville,

Lincolnshire,

Lincolnwood,

Long Grove,

Morton Grove,

Mount Prospect,

Niles,

Northbrook,

Northfield,

Oak Park,

Park Ridge,

Prairie View,

Skokie,

Vernon Hills,

Wilmette,

Winnetka

WickRight Passive Ventilation® and WickRight Vapor Release Systems® are a line of United States Patented products owned by WickRight, Inc., including WickRight Metal Coping Vent™, WickRight Capstone Vented Drip Edge™, WickRight Vented Receiver Clip™, WickRight Roof Vent™, WickRight Hip & Valley Vent™, and WickRight Perimeter Vent™ owned by WickRight Inc. WickRight Passive Ventilation®, WickRight Parapet Vent® are registered trademarks of WickRight, Inc. WickRight™, WickRight Vapor Release Systems™, WickRight VRS™, WickRight Metal Coping Vent™, WickRight Capstone Vented Drip Edge™, WickRight Vented Receiver Clip™, WickRight Roof Vent™, WickRight Breathe-Weep™, WickRight Hip & Valley Vent™, WickRight Perimeter Vent™, Buildings Breathe Right™ are trademarks of WickRight Inc.

365 Construction Tents™ are a United States Patented product owned by WickRight Inc. 365 Construction Tents™ is a trademark of WickRight Inc.

WickRightGeneralContracting.com • © WickRight General Contracting, LLC 2016 All Rights Reserved • Website Designed by Knight Advertising Design, Inc